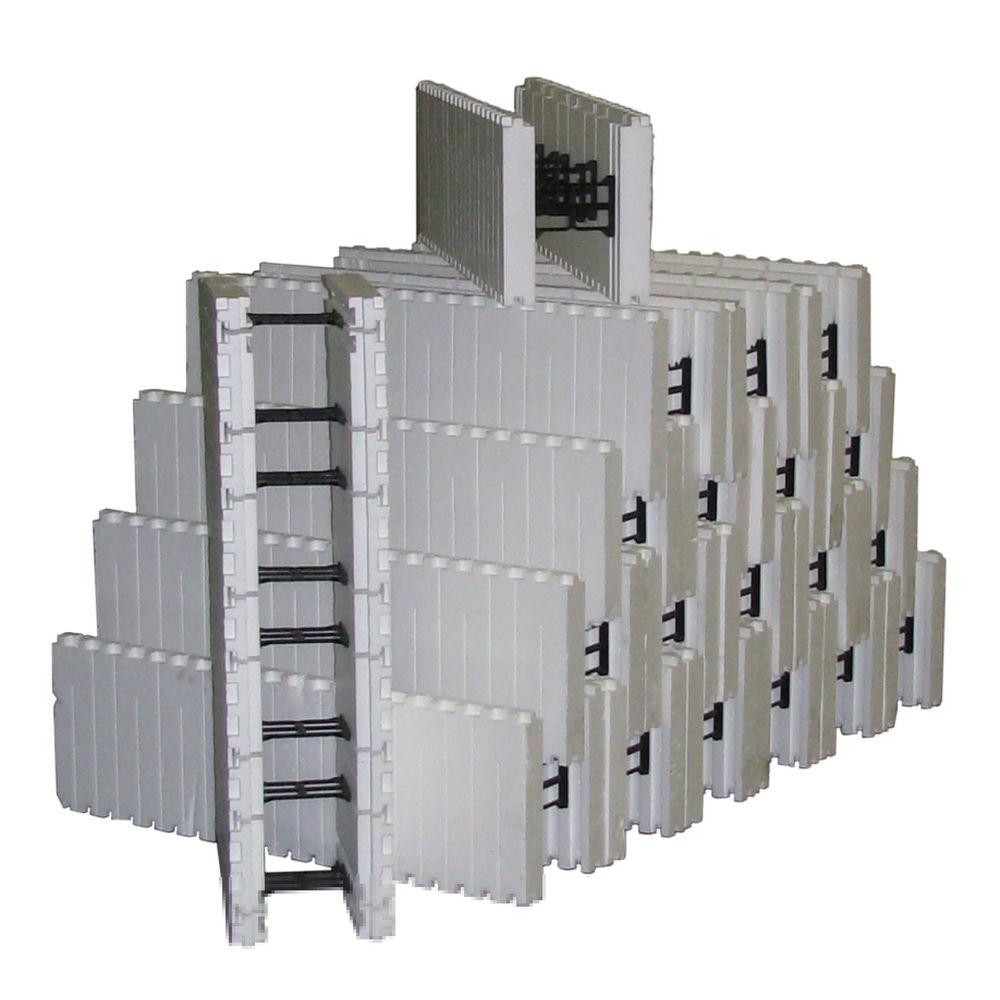

The diamond snap tie connector creates a cavity for the concrete between two faces of 2 high density foam control with perform guard.

Snap together foam concrete wall construction.

Snap tie concrete forms are a simple and easy system for foundation walls.

If your wall will be less than 8 feet in length place two nails to mark the end of the wall.

Of eps on each side.

This concrete form panel is a large tough quick setup panel with snap together edges that form a strong straight flat pre finished wall greatly reducing your setup and finishing time.

The finished wall will be 5 75 in.

The choice of fastener for styrofoam extruded polystyrene foam insulation is completely dependent on the application.

The panels when snapped together form a continuous foam interface for maximum energy savings.

Place nails marking the outside faces of your wall at least 8 feet apart down the planned length of your wall.

Thank you for all your support https www paypal me mountainhomestead essential.

If you are looking to save money b.

It is constructed as a load bearing structure to transfers loads from floor to the wall below or to the foundation in addition to divide spaces in multi storey buildings.

They are a lightweight polystyrene eps stay in place concrete form that speeds construction and yields a highly insulated wall.

Lightweight precast concrete panels find complete details about lightweight precast concrete panels wall panels lightweight foam concrete concrete foam panels snap together from sandwich panels supplier or manufacturer yantai feilong international trading co ltd.

Snap tie concrete forms are a simple and effective way for anyone to be able to pour concrete effectively and inexpensive.

Moreover concrete wall is a desirable structural element in earthquake prone areas since it exhibit.

The dsf icf system remains in place after the concrete is poured serving as wall insulation and attachment base for facing material.

Construction of concrete walls is a crucial phase in building construction.

There is less settling or compressing less moisture absorption or dust saturation and considerably fewer cavities that permit convection or air circulation than in conventional framing methods.

Acoustical applications and fire retardant properties increase the value of this construction method.

You can consult your local construction supplier for advice on which fasteners should be used for a particular application.

This way you can see where your wall is.

There are many fastener manufacturers located throughout north america.